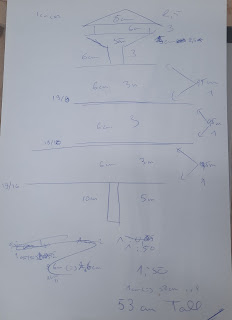

3d outcome: metal workshop

With the help of the technician and the induction that we had done before, I was able to cut a steel pipe into 4 equal cylinders that I will use as the pillar. Each one is 53cm tall with a diameter of 1cm. I used a piece of machinery to cut all the pieces the same, it was an easy process because this machine has a fixable point of reference to know the exact size. This is an accurate representation of the real-life material because I have decided that it will be steel.