Term Reflection

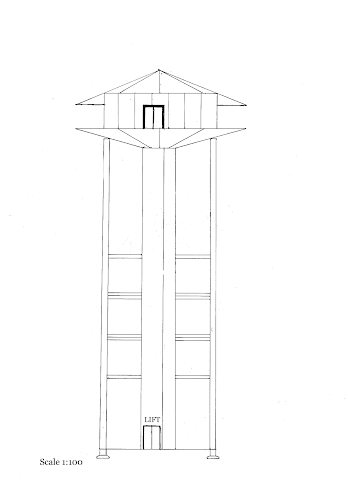

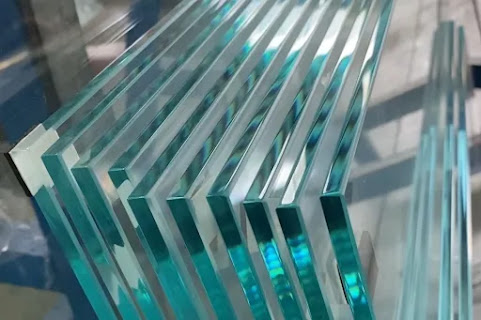

Click on image to access the link. This term had its complications surely,, all in all, I believe that it went well and I am happy with the outcome. Even though this term was challenging, it has helped me improve a lot of my skills, particularly with scaling, drawing, and 3d model making. Furthermore, it was intellectually nourishing to start from scratch with an idea and constantly coming back to it. I gained a lot of knowledge from this endeavor, which was a positive experience. I have learnt how to sketch my idea, research about it, develop it, accommodate the project for the client and their needs, etcetera. the workshops have been an important experience where I have learnt many skills. Throughout this term, I was not only able to document my process but also showcase my way of thinking about the project as well as my critical mind. In conclusion., I can say that this term was fairly satisfying in terms of outcome and the overall knowledge that I have learnt through this module.